Can you make your own fittings?

Now I don't mean simple stuff like my tack inhaul or the boom slider. I mean the sort of stuff you might buy from a chandler. I did mention mast chocks in my article about mast rake and you can easily make a mast chock yourself from a bit of wood or plastic using basic tools like a saw and a file, But they don't look quite as nice as the professionally made ones from Allen for example. Now Allen Brothers are a British company, but quite a few fittings are made in America or China. Often the imported fittings are very good, but I like to think that we can make some of that stuff ourselves. Might be better for the planet too.

So what can we do ourselves as amateur sailors? Certainly not everything, but I thought I would explore what could be done with a bit of help from modern technology.

Now I know very little about 3D printing and CNC machining but they are both production systems that are controlled by computer. My day job is computer software development - I work for a very large computer consultancy and they lend me out to other large companies, mostly for web site development work. The trouble is, to make anything with either production method you need to come up with a design. I am no designer and I know 3D design software can be difficult to use.

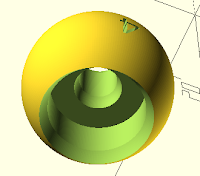

But recently I came across some free software called OpenSCAD which lets you do 3D modelling by writing code - no design or artistic skills required. Seemed right up my street, so I gave it a go. And I have to report - it is rather good. Now there is still plenty to learn, but it is achievable with a bit of effort. Here is a mast chock I designed

and the cool thing about design-by-code is you can make it configurable. So above is an 8mm thick mast chock, but by changing a parameter in the code I can make a 5mm thick mast chock without any extra work.And my code even carves a 5 into the chock rather than an 8. Some of you are thinking "that's cool" and the rest "you are a nerd" 😎I have a couple of ideas for other fittings too. It is nice to have the option to design your own. Something new to while away the winter days when I can't go sailing ⛵

Comments

Post a Comment